Ask any of our customers, "What's the number one benefit that separates Norwalk Precast Molds from the competition?" The answer will be, "Quality." Everyone will agree that a Norwalk Hydra-Strip® mold lasts longer, is easier to control, is more economical and performs better than any other. We attribute that dependable quality to our Hydra-Strip® design, the very best in automated precasting equipment.

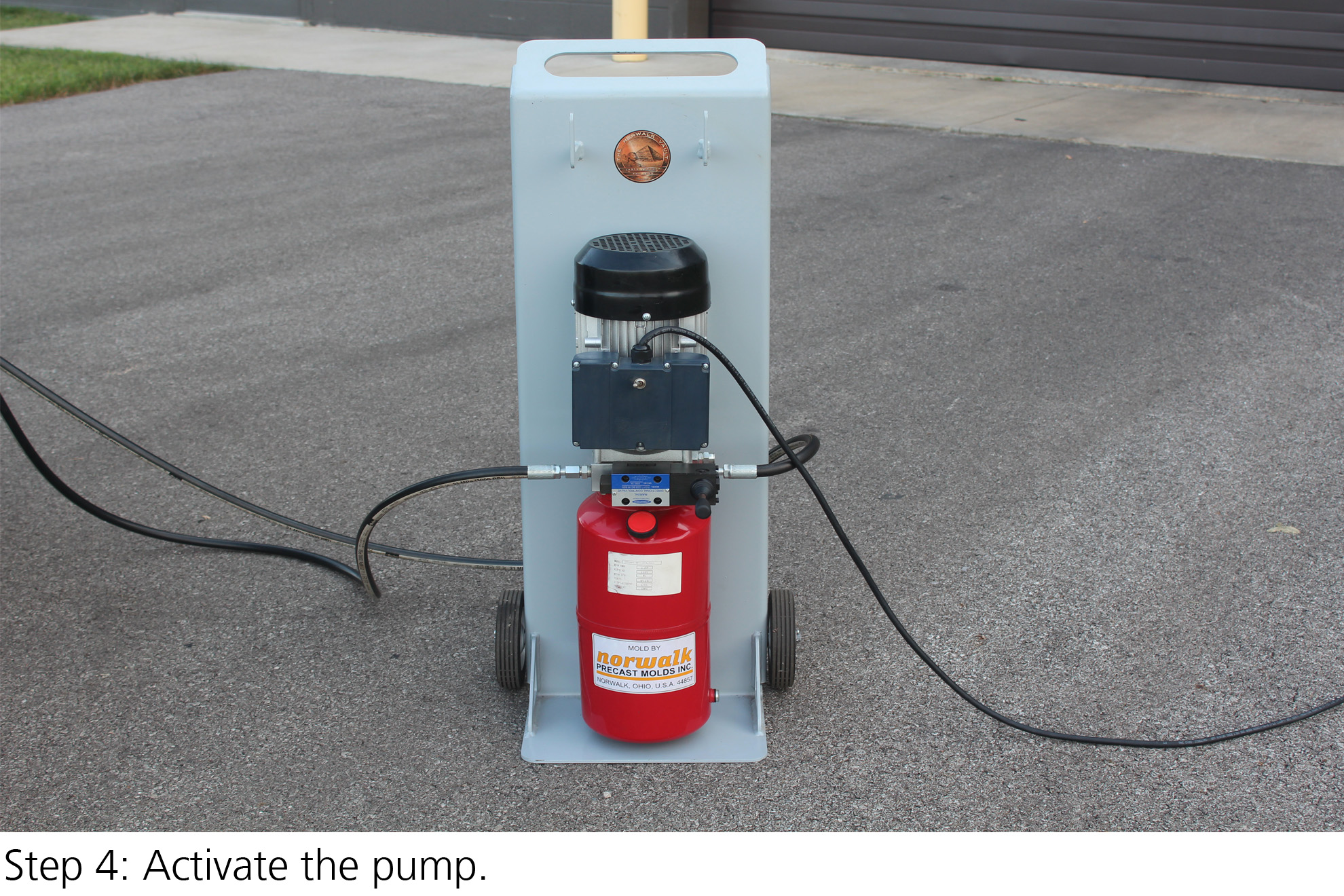

Norwalk Precast Molds' patented Hydra-Strip® design produces a more manageable and longer lasting mold than any other in the marketplace. Here's how this unique hydraulic operation works: a hydraulic cylinder rotates two shafts; on each end of the two shafts there is a hardened steel cam. As the cam rotates it raises four pistons, two on each long side of the mold. These pistons release the casting from the mold core. This all happens within minutes! Due to the design of this mechanism, our Hydra-Strip® system insures that each of the four push pistons are perfectly timed to guarantee a fast, smooth, jam-free stripping of the mold. This patented design is just one example of how we are saving our customers time and money with each casting.